By Don Steen

Staff Writer n reporter@psci.net

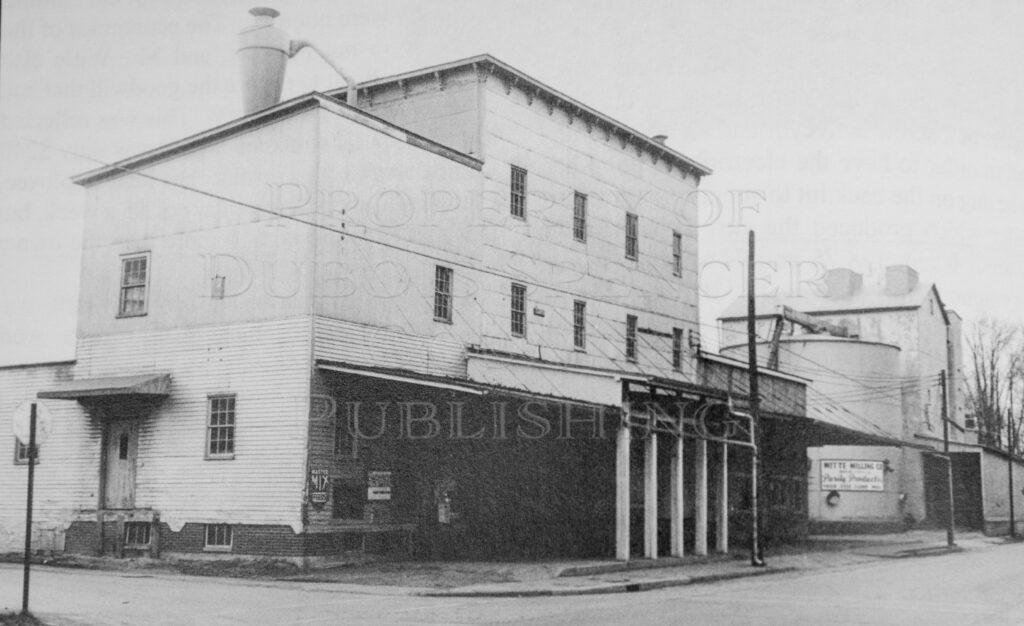

The skyline of Dale changed last week as the historic Witte Mill building was taken down piece by piece. The mill has stood since the mid nineteenth century, survived a fire in 1994 and remained in operation all the way to end. Much of the equipment inside was still technically functional, although the mechanisms (many of them wooden) would not be out of place in a museum. While the historic mill is gone, the site will remain in its traditional feed business under the ownership of Reckelhoff Family Feeds, who recently purchased the property from the Witte Family.

In charge of the removal was Danny Landers of Barns B Gone, a company specializing in the demolition and salvage of old farm structures. The Witte Mill is a bit more complicated than most projects, spanning multiple floors with a variety of heavy equipment and other features installed over the last 178 years. Still, it’s decidedly in his crew’s wheelhouse.

“This is about the same,” said Landers.

A history of the Witte Mill, including pictures from throughout its long life in Dale, can be found in local historian Daryl Lovell’s book, Dale, Indiana 1843-1993: [Continuing the Pioneer Spirit, 150th Anniversary]. A copy of this book, along with other information on the mill, can be found in the Lincoln Heritage Public Library’s genealogical room.

The mill was originally built by the Wallace Family, sometime around 1847 and was initially used for steam flouring. The business steadily grew as other members of the family bought into the business. By 1886, A. Wallace & Bros rebuilt the mill and replaced the old-buhr millstone system for a more modern full roller process at a cost of $10,000, an investment of more than $340,000 factoring in inflation.

Further improvements included the addition of electric appliances, including blow dryers, which greatly increased productivity. Prior to this upgrade, wheat had to be left in the field until it contained only 15% moisture to avoid spoilage, and even then required strenuous labor by mill workers to physically turn the grain with large wooden shovels. Kerosene lamps were required to keep the mill lit during the winter months.

Electric power allowed grain to be turned by transferring it from one bin to another by means of a powered screw conveyor and an elevator leg. It also meant that electric lights could be installed.

The mill needed its own power source, however, so a pond was dug on the back of the property. That water was then used to generate steam from a boiler, with which the motors could be run. The mill required 75 barrels of water to run its engine a full 24 hours.

Prior to the creation of the pond, water had to be hauled by wagon. Dale residents also made good use of the new pond for recreation.

The mill was briefly leased to Erskine Milling Co. of Evansville during World War I, but was returned to the Wallace Milling Company in 1919. The mill fared well producing corn meal, flour and other staples until the Great Depression hit in 1929.

Faced with bankruptcy, five of the six stockholders tried in vain to keep the mill running, but the business went into receivership. It was then purchased by Elmer Winkler, who happened to employ Ernest Witte. Within a year, Winkler sold the mill to Witte for $5,000, or about $96,000 today.

Witte faced a hard business environment. The Great Depression had only just begun, and it was hard to climb out from the shadow of a recent bankruptcy. His first year’s income was only $240. His lone employee, Clarence Elliott, drew a salary of $5 a week, technically more than Witte himself.

The newly minted Witte Mill endured, however. A hammer mill was installed to grind grain, feed mixers to mix feed and a molasses mixer to sweeten the dairy feed.

In 1942, R.G. (Gail) Witte, son of Ernest, began working at the mill after school and on Saturdays. In addition to his other duties, he was tasked with making as many as 40 or 50 stops to sell feed and flour to small stores across the area. At the age of 16 he was tasked with picking up product in St. Louis.

The younger Witte took a brief respite from the work of the mill from 1944 to 1947, when he served in the Naval Air Force and studied at the University of Illinois. After graduation though, he came home to become a partner in the business.

The Witte Milling Company manufactured feed, flour and corn meal under the name, Purity. More grain storage was added through the years, along with other upgrades. Their business gradually expanded to providing dog food and horse feed, as well as feed for game birds and rabbits.

The elder Witte retired in 1958, leaving Gail as the head partner and eventually president and general manager. In 1974, Ernest passed away peacefully in his office after putting in one last day of work at the mill.

Fire was always a concern. The original fire-protection system centered on water kept in 50-gallon crock barrels placed on each of the three floors. This was upgraded throughout the 20th Century, but prevention only goes so far.

The mill was the scene of a major fire in 1994, but was able to emerge relatively intact and continued to operate. In fact, the facility was still in operation until it was sold.

Local resident Ruth Swinghammer said she had a lot of memories of the old feed mill, and was sad to see it go. She recalled how her family would buy their feed from there, and repurpose the sacks for clothing material and other uses. As it happens, those burlap sacks aren’t the only part of the Witte Mill that will wind up seeing a second life.

Even now, the history of the Witte Mill isn’t quite over. Landers pointed out that the lumber from the structure is being salvaged. The old nails were painstakingly removed, and the boards kept intact.

The historic hardwood is being sent to Old World Timber of Lexington, KY, a company specializing in reclaimed wood products. Bits and pieces of this Dale landmark could soon be found in flooring, walls, furniture and all number of products across the world.

“Whatever you can imagine,” said Landers. “A hundred years from now it’ll still be around.”

Featured Image: Danny Landers of Barns B Gone (at right) leans out of a freshly made hole in the second story wall of the Witte Mill to make sure it is safe to drop a board down while Tad Smith (left) prepares to loosen another.

Pictured from left: The mill as it stood in 1870, when it was still the Wallace Milling Company. The mill in the 1970’s, long after the Witte Family took ownership. — Both photos courtesy of Daryl Lovell’s sesquicentennial history of Dale